Design Advantage

Recognized for our craftsmanship and high quality, All American Marine has attained exclusive North American building rights with one of the world’s top naval architects and designers, Nic de Waal of Teknicraft Design, Ltd. in Auckland, New Zealand. The unique Teknicraft design incorporates the use of a cutting-edge hull shape and an optional hydrofoil system in catamarans to create lift and enhance the performance of the vessel. Unique design characteristics ensure high-speed travel, ultra-low wake, industry-leading fuel efficiency, and all fully customizable depending on the application. With vessels ranging from Pilot Boats to Crew Transfer Vessels, Passenger Vessels to Dinner Cruise Monohulls, All American has the ability to build any Teknicraft Design, right in our state of the art Bellingham, WA shop.

Teknicraft hull designs have been recorded as producing one of the lowest levels of wake wash energy within their vessel class as well as incredible fuel efficiency. The latest in quad engine and waterjet propulsion methods that are incorporated into construction lead to revolutionary fuel efficiency that often exceeds expectations, even with fully-laden vessels. A Teknicraft Design offers performance advantages unlike any other. The customization potential for both form and function across a variety of industries is the differentiator in our design and construction. Our design team works directly with each operator to transform their visions into reality. And whether it’s a workboat or high-speed passenger ferry, All American Marine manufactures the highest quality boats in North America, and it all starts with a custom yet proven design.

Hull Shape

The unique shape of the Teknicraft catamaran hull lifts and enhances the performance of the vessel while maintaining a smooth ride and industry-leading efficiency. The catamaran hull form is a semi-planing type catamaran and employs a combination of symmetrical and asymmetrical sponson shapes, thereby combining the attributes of both shapes into one hull. The symmetrical bow-section ensures directional stability in rough conditions, while the asymmetrical midship and aft sections ensure softness of ride and reduce the wetted area, enhancing comfort and fuel economy, as well as decreasing wake energy. Our catamarans feature a high and wide tunnel between the semi-planing demi-hulls, allowing free passage of wind and waves underneath without harsh contact against the underside of the deck above. Teknicraft developed the extended bow (“eco-bow”) of the demi-hull shape to further enhance the already excellent seakeeping characteristics of the Teknicraft signature hull shape. The hull extensions are shaped to have very little freeboard, whereby they significantly reduce vertical accelerations in choppy seas whilst also reducing pitching motion. The extended hull length reduce rolling motions when operating in quartering seas, whilst straight tracking is enhanced in following seas. Together, these characteristics ensure that the seakeeping is enhanced, resulting in a softer ride and more comfort for the crew, particularly in rough seas. When operating in calm seas the extended bow is completely free of the surface, ensuring that the low resistance of the Teknicraft hull is not affected in any way. The extended waterline length of the hull increases the displacement speed, whereby the maximum range at low speed is increased by approximately 6%.

Customizations are endless depending on your vessel’s unique application!

LOW WAKE

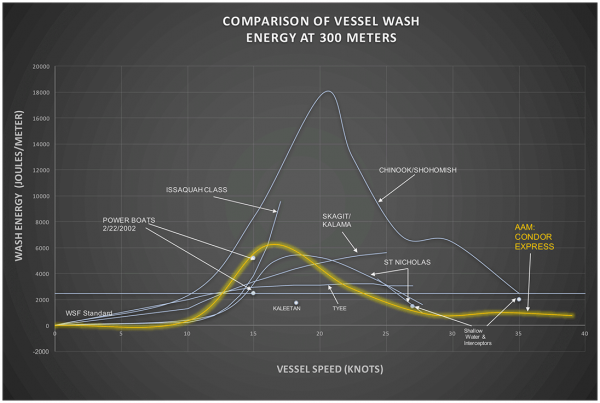

As a result of a federally funded research project, Kitsap Transit, underwent a study to not only implement a beach monitoring system for erosion, but also brought on All American Marine and Teknicraft to research a low wake wash vessel design.

With the community and mission in mind, a wake propagation model was developed to predict vessel wake parameters (i.e. height, period, direction, and phase) at the shoreline along the proposed ferry route. This model was used to evaluate the potential effects of alternative fast ferry operations on shoreline erosion and sediment transport.

The ultimate goal was to evaluate potential shoreline protection solutions for areas where the impact cannot be minimized. Using a Computational Fluid Dynamic (CFD) Modeling Automated Systems-Based Design, tank testing, and a vessel optimization study featuring 3 different hull shapes, 3 different hydrofoil profiles, and 9 new vessels, Teknicraft and All American Marine designed and built the Rich Passage. It is the lowest wake wash vessel in its class, setting a new standard in hull design. A huge win for our operators working in sensitive areas, and applicable to many vessel types and industries where erosion and environmental impact need to be considered. Read more about the study and how All American Marine with Teknicraft built the Rich Passage.

Fuel Efficient

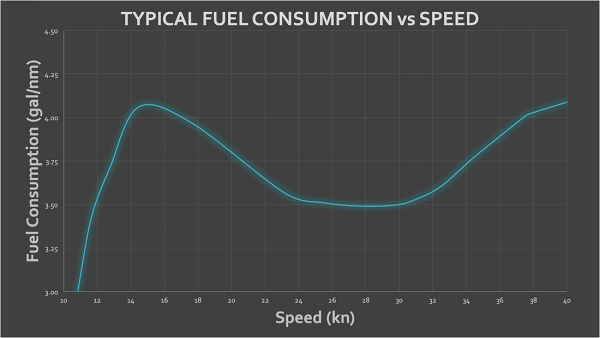

“During sea trials, the difference in fuel consumption between light and fully laden at cruising speed was almost negligible, which means we’ve cracked the code in terms of [low] fuel consumption at high speeds.”

– Nic de Waal, Teknicraft Naval Architect

Whether it’s long excursion patrol or research vessels, to multi-trip passenger ferries and eco-tours, fuel costs are always a significant factor in purchasing a vessel. That’s why we work tirelessly in the design phase to customize each hull for its intended application, and as a result, our catamarans and monohulls often exceed fuel efficiency objectives across the board. Our vessels pay for themselves over time and we look forward to showing you how.

Technology

Hydrofoils

Hydrofoils can be incorporated into many of the All American Marine catamarans to aid in speed, performance, and efficiency where the specific application may require such enhancements. Our unique hydrofoil system consists of the main foil spanning the tunnel at the keel, forward of the center of gravity position and two cantilever-type stern foils. The lift produced by the hydrofoil reduces the hull resistance, while increasing speed and load-bearing capability.

The stern foils create a vertical lift at semi-planing speed, which reduces the trim angle when getting on step. This significantly reduces both the power requirement and the wake wash in the low-speed range. The main foil action reduces the power needed to maintain service speed; therefore, fuel consumption and running costs are reduced significantly, while also further enhancing the softness of the ride, especially in choppy seas. We have years of experience testing and building both aluminum and composite adjustable hydrofoils, depending on the application of each vessel and where appropriate.

Displaces 1/3

of the

Vessel’s Weight

Uses 1/3 less horsepower on average

Burns 1/3

less Fuel

on average

Hybrids

All American Marine has made a commitment to shaping the future of hybrid technology, and is charting a new course. Where many see a tough transition, we see a new opportunity to help our operators lead the charge and be a part of this revolution in shipbuilding. We work with each client to assess the long term social, environmental, and financial impact of their vessel and help them make the decision on how to utilize new technologies to meet or exceed their objectives.

Our experienced team of experts is available at each step of the design process to ensure all propulsion options are thoroughly explored. Only the best systems suited for each vessel’s specific route and application are incorporated into the project. This is why we partnered with BAE Systems to build the Enhydra for the Red and White Fleet in San Francisco, a lithium-ion powered monohull that will carry passengers to multiple points around San Francisco Bay.

What technology is really available? What’s coming in the near future? What can be expected in terms of fuel consumption and actual emissions levels? Will this system fit into my boat – large and heavy? Will my vessel still be able to make the speed and efficiency required of my specific mission? There are many questions and even more answers. All American Marine is here to help guide our operator’s through the noise to find a truly sustainable and valuable solution.

Construction

All of our vessels are built in a state-of-the-art 57,000 sq. ft. production facility adjacent to Bellingham Bay. The production shop contains 7 overhead bridge cranes, a brake press, shear, CNC router cutter, and a laser-leveled construction platform. We follow a stringent quality assurance program where each craftsman has committed to paying careful attention to detail and ensuring the highest levels of quality. Depending on the vessels application, we ensure stringent regulatory compliance including US Coast Guard vessel certifications. USCG visits weekly and does inspections and performance checks throughout the production process.

From production techniques to employee best practices, AAM is committed to building a dedicated workforce of well-trained craftsmen. Our cohesive team is our secret to adding value and building the best boats for our operators.